At Aratron we want you to expect added value as standard. For this reason we tailor our products to meet the needs of our customers, not the other way round. This attitude means that three quarters of everything delivered from our engineering workshop in Järfälla has undergone some form of customisation.

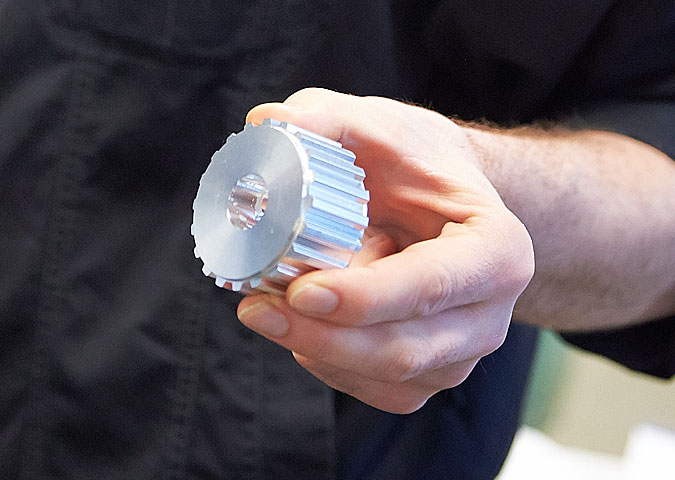

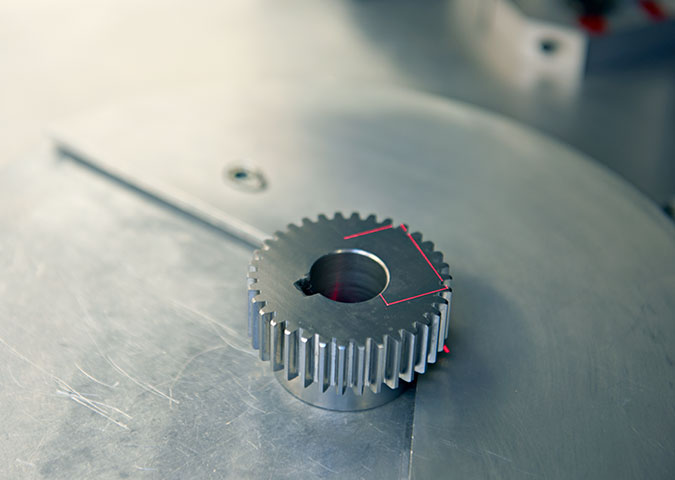

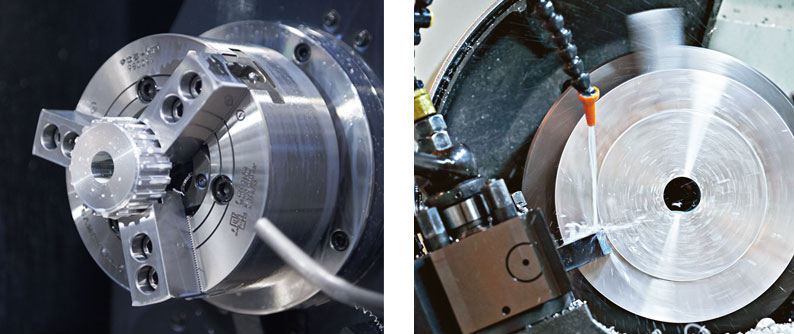

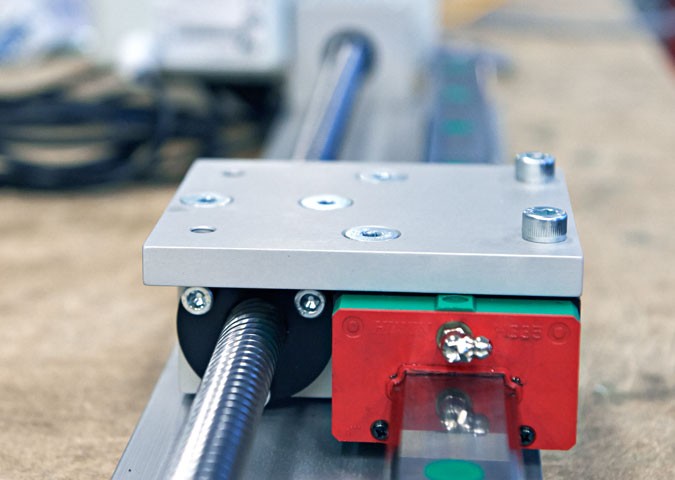

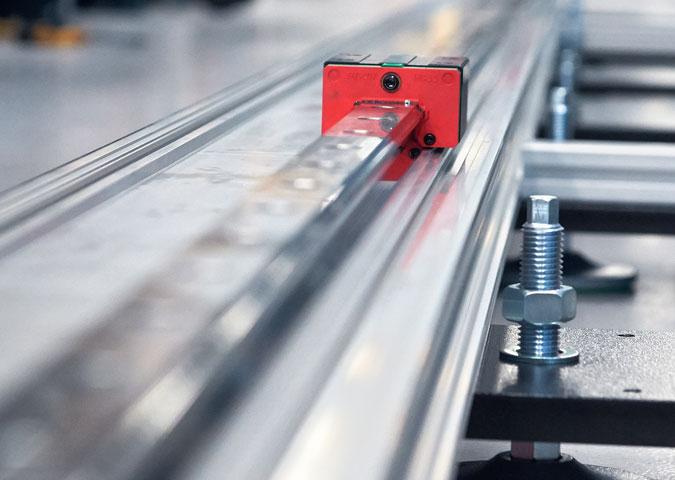

Here in the workshop we manufacture our world-renowned timing belt pulleys (more about them below), but we also have the in-house production and customisation of linear units in aluminium profiles, driven either by a timing belt or ball screw and with either roller bearings or a linear guideway. In addition we process products by cutting rails, end machining bolt screws, cutting timing belts, filling gas springs and assembling subsystems.